VALUE ADDED

SERVICE

☑ IML FILM WITH CUSTOMIZED SIZE / SHAPE

☑ PRINTED & CONVERTED IML LABEL - PROTOTYPING

& MASS PRODUCING

DMT IML film comes as jumbo roll in most cases. At the mean time, we are also able to make them in customized size and shape at request.

Also, there are a few of our customers who are buying finished IML labels through us, as our out-source supplier for printing are normally DMT customers for IML film, we can get quite competitive price.

INTRODUCING IML

IN-MOLD LABELLING (IML)

In-mold labelling (IML) is a new method popularly used in decorating injection molded parts, such as plastic containers, consumer product parts etc.

During molding process, pre-printed in-mold label is placed into the mold before molten materials are injected; the remaining temperature of the material fuses the label with the container, makes it an integral part of the product.

Comparing with traditional way for label printing - spray painting or pad-printing - IML allows higher quality graphics , better water-proof property and greater wear resistance. By combining the decoration process with the molding process, IML simplifying production process and reducing cost.

With such advantage, in-mold labelling is becoming preferable for industry, such as food, health care, chemistry etc.

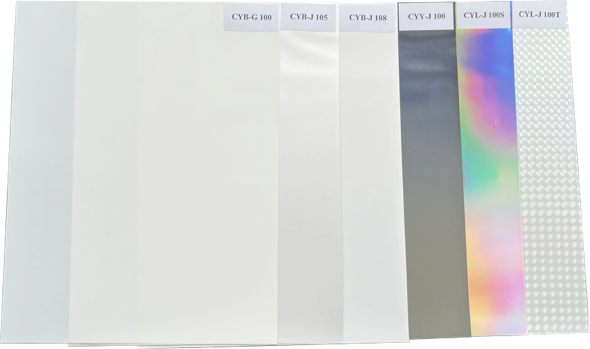

IML FILM MODELS

Free Sample Available, Only Freight to Pay

TYPE

Blow Molding

Injection Molding

MODEL

CYY-G100

CYB-J105

CYB-G100

CYL-G100S

ZUB-J6060

ZYB-G6591

ZYY-G80

ZYL-G80

ZUT-G65

* Customization: Film Thickness, Roll Width, Film Length

THICKNESS

μm

100

107

100

100

60

100

107

100

100

DENSITY

g/m³

0.87

0.77

0.84

0.87

0.60

0.87

0.77

0.85

0.87

GRAM

g/㎡

87.3

82.3

83.6

87.3

36.0

87.0

82.7

85.0

87.0

GLOSS

Print/Rear

-/21%

7%/21%

7%/21%

-/21%

100%/18%

-/21%

7%/21%

7%/21%

-/21%

WHITENESS

Gross/Matt

-

87%

90%

-

80%/83%

-

87%

90%

-

OPACITY

-

87%

88%

-

85%

-

87%

88%

-

IMPEDANCE

Print/Rear

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

1*10^11/1*10^12

TENSILE STRENGTH

MD/TD

110Ω/203Ω

85Ω/149Ω

110Ω/203Ω

110Ω/203Ω

50/115

110Ω/203Ω

85Ω/149Ω

110Ω/203Ω

110Ω/203Ω

PRODUCT FEATURES

☑ Excellent printing performance, support multi type of printing methods

(conventional printing, UV offset/flexo printing, gravure printing etc)

☑ Quick drying, gorgeous color

☑ Good chargeable performance assure good adhesive property in the mold

☑ Low static, easy for die cut transforming and robot arm operating smooth

☑ Good temperature resistant, suitable for container body and caps

☑ Suitable for PP containers

IML APPLICATIONS

In mold labelling is widely used in in-mold blow molding, injection molding, thermal forming, blister process, PSA labels etc.

IML containers are becoming popular in various industry such as food & beverage, daily article, cosmetic and petrochemical etc.

Products applied IML technology in packaging provides superior quality finish and more stunning appearance to customers, it's becoming a preferred choice for high end consumer products.

DESCRIPTION

Silver Gloss

White Orange Peel

Smooth White

Holographic

White Orange Peel

Smooth White

Holographic

Silver High Gloss

Transparent Gloss